Presentation

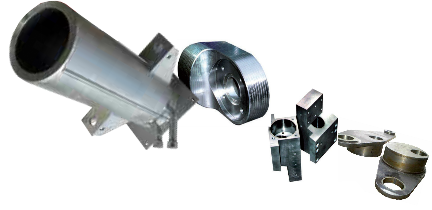

Established in 1924, MECAJET SAS is a company with 45 collaborators and specializes in engineering, key in hand installation, new works, special machines, mechanical construction, mecano-welding, pressure vessels, machining, and railway equipment and material.

Means of study – Calculation – Engineering

- Building of 2D-3D models

- Calculation notes

- Modelling

- Digital command solutionses

Means of production

- Lifting equipment: 10 tons

- Digital command towers

- Stroke: 5,000 mm

- 1250 mm detached diameter

- Digital command machining centre

- Stroke: 7,000 mm x 1,700 mm x 1,250 mm

- 3 and 4 axes

I.e. 12 digital command machine tools

Other means

- Liquid paint cabin

- 6000 mm x 5000 mm x 3000 mm

- Sandblasting

- A full assembly kit

Means of control

- FARO arm

- Measuring column

- NDT

- Dye penetrant

- Magnetoscopy

- Use of a strain gauge to acquire data on fatigue

Site topography

- Total surface of 17,500 m2

- Covered surface of 5,500 m2

Welding

- 20 TIG/MIG/MAG power generators

- Steel, aluminium, stainless steel welding

- Reloaded hammers, rollers, Stellite finger and a highly durable product.

- Robotised welding method on 8,000 mm suspension levels/working volume 3m2

- 15085 class 1 et 3834-2 certified

Information systems

- Production management with GPAO ERP Solune

- Globalisation of our organization managed by our QSE system

- Computer-aided technology with SolidWorks and Solid CAM

Training plan

- 3500 hours a year

Our fields of activities

Aeronautics – Food & agriculture – Automotive – Cabling – Carton industry – Cement industry – Cosmetics – Agricultural material – Railway material – Medical – Nuclear – Stationery – Pneumatics – Taps – Steel industry – Sugar refining – Textile – Tunnelling – Glassware

Develop comprehensive capacities, use training to strengthen our level of competence in order to support our customers in their the most complex projects and strategic, by remaining vigilant on the accompaniment of men, to live in the image of the Vitruvian Man, with proportionate collective development.

Develop comprehensive capacities, use training to strengthen our level of competence in order to support our customers in their the most complex projects and strategic, by remaining vigilant on the accompaniment of men, to live in the image of the Vitruvian Man, with proportionate collective development.

F.X. JETTE, President